What is Infrared Heating?

Infrared heating has gained significant attention in recent years as an innovative and energy-efficient heating solution. As a trusted UK manufacturer with over 40 years of experience, Tansun brings you a comprehensive overview of infrared heating, its various types, and how it compares to other heating alternatives. In this article, we delve into the concept of infrared heating, explore the differences between short, medium, and long wave infrared heating, and discuss why conventional heating solutions may not be suitable for heritage, commercial, and industrial settings aiming to achieve net-zero targets. We also highlight some thresholds of infrared heating to consider when seeking an all-round heating solution. At Tansun, we pride ourselves on being experts in the field, offering dedicated support to help you determine the best heating options tailored to your specific needs.

What Does Infrared Heat Do?

To begin with, an introductory explanation of infrared heating sets a clear context. Infrared heating utilises invisible electromagnetic waves to directly heat objects and people, rather than heating the surrounding air like traditional heating systems. By emitting radiant heat, infrared heaters provide quick and efficient warmth, mimicking the sun's natural heating process. This unique characteristic makes them ideal for a wide range of applications, from domestic spaces to commercial and industrial settings where the focus is on heating occupants. Electric radiant heaters create a direct infrared beam which heats people and objects in its path. A quartz element can be incorporated in the housing to produce and emit infrared heat. Shortwave infrared heaters can be characterised by their effectiveness and ability in providing quick warmth without the need for pre-heating, however there are various different forms of infrared heating which we discuss below:

Understanding Infrared Heating - What is it? What Does it Do?

Infrared heating can also be classified into three categories based on the wavelength of the infrared radiation: short, medium, and long wave. Though this may appear confusing to some, each type offers distinct characteristics and applications; delved into next.

What is Short or Near Wave Infrared Heating?

Short wave infrared heaters generate intense penetrative heat instantaneously as soon as they are switched on and are not affected by air movement such as draughts. Up to 100% of energy is therefore typically emitted as heat quickly, with only minimal losses heating the space. This makes them suitable for high-intensity applications or specifically impossible to heat areas which require focused heating. When mounted correctly at the appropriate height, the intense heat can thus be distributed to provide targeted warmth to areas with larger occupancies, heating where needed.

What is Medium Wave Infrared Heating?

Medium wave infrared heaters strike a balance between intensity and efficiency, making them versatile for various heating needs. Though the heater takes on average only 30 seconds to warm up, less energy is emitted as heat (up to 60%) given that medium wave infrared heaters are more susceptible to air movements. Medium wave infrared heating is therefore typically suitable in specific applications where there is less air movement and a slightly gentler form of heat is desired.

What is Far Infrared Heat?

Long wave or far infrared heaters emit gentle and prolonged heat, creating a comfortable and consistent heating experience. On average these heaters take around 5 minutes to distribute heat. However, with a less intense wavelength, less energy is emitted as heat (up to 40%) as long wave or far infrared heating is heavily susceptible to air movement. Long wave infrared heaters are therefore a suitable choice for gradual heating of well-enclosed spaces with little draughts or changes in air movement. Generally within an industrial application such as factories and warehouses where there are roller shutter doors opening and closing, long wave is typically not well-suited in this scenario as heat will be lost.

What is Better? Infrared or Gas Heating Systems?

Comparing Infrared Heating to Other Heating Solutions

Gas-fired Systems:

Plans to fully decarbonise the UK economy by 2050 has led to an abundance in commercial, industrial and heritage organisations seeking greener alternatives to gas-fired systems which do not burn fossil fuels (C02). Though gas-fired heating systems have been the ‘traditional’ solution to heating, they are viewed as increasingly outdated due to their large structures, maintenance regimes and servicing requirements. The carbon footprint of heat generation is widely cited. Recent figures show that nearly 50% of the fossil fuel gas consumed in the UK annually goes on heating. Overall, use of gas-fired systems is a solution which is at odds with business carbon neutrality targets, given their focus on heating the whole volume of space which results in high emissions outputs.

Gas, Oil, and Electric Warm Air Blowers:

While conventional heating solutions like gas, oil, and electric warm air blowers have been widely used, they often fall short in meeting the requirements of heritage, commercial, and industrial settings aiming to achieve net-zero targets even when coupled with destratification. These systems still aim to heat the whole building volume resulting in energy wastage, uneven heating, inefficient distribution and higher energy consumption. One study compared unit heaters/blowers and radiant heater performance in a 20 ft. (building), finding that radiant infrared heaters consumed about half the energy to heat the same space.

Ground or Air Source Heat Pumps:

Heat pumps are known for their energy-efficient operation by extracting heat from the environment (typically air-source or ground source). However, prohibitive installation and maintenance costs limit their consideration as a cost-effective heating solution for businesses. For instance, the typical cost of a commercial air source heat pump unit varies at approximately £6,000 - £18,000, scaling beyond this figure if multiple units are required in larger spaces. Ground source heat pumps come in at much higher variations between £14,500 and £45,000 depending on the type of ground source heat pump installed.

Installation fees are also dependent on the amount of groundwork required per unit, plus any considerations needed to improve insulation in order to maximise efficiency. In context, the average temperature output of a heat pump is impacted by external temperatures which makes them less effective in the winter months and building conditions. For less-insulated buildings or retrofit spaces where heat losses can occur this is an important consideration. The size of and age of the building plays a fundamental role in determining whether heat pumps are a viable and cost-effective solution, given the volume of space which needs to be heated and the temperature losses which can occur. Naturally for a larger and older building such as a factory, warehouse, facility or historical building, the total cost of heat pump installation can be much higher when considering all the requirements for the size of the space.

In many cases, heat pumps are therefore used alongside supplementary heating systems such as underfloor heating to maximise heat pump temperature output within existing spaces such as factories, warehouses and historic or heritage buildings. However this solution also requires additional ground work plus added system and labour costs. Disruption during installation thus persists as a major barrier to the uptake of heat pumps within the UK, leading to discussion surrounding more suitable low-carbon technologies which meet demand, are cost-effective and are more suitable for certain retrofitting projects.

Underfloor Heating:

Underfloor heating systems distribute heat through the floor, creating a comfortable and even warmth. While suitable for some applications, underfloor heating can be expensive to install and may require significant structural modifications, making it less practical for retrofitting existing buildings. Hourly system operational costs are another consideration, particularly as underfloor heating can take time to reach optimal comforting temperatures in less-insulated conditions. Potential faults with poor insulation, wiring issues, leaks or problems with screed also need to be carefully considered in order to avoid costly infrastructural challenges or sectional floor excavation. On a whole, installation and operational costs over a period of time are likely to give businesses food for thought on the suitability of underfloor heating for their building type. Other low-carbon technologies with lower installation costs which are less disruptive may again be the appropriate solution for this scenario.

The Cons of Infrared Heaters - Is it Right for Your Project?

It is essential to consider the capacity of infrared heating when evaluating it as part of an all-round heating solution. Some factors to consider include:

- Directional Heating: Infrared heaters emit heat in a specific direction, requiring careful geometrical placement for optimal coverage. This characteristic necessitates thoughtful planning to ensure efficient and uniform heating throughout the desired area. In some cases, organisations fall short of considering this step.

- Line of Sight: Infrared heating requires a clear line of sight to effectively heat objects. Obstacles such as furniture or partitions can obstruct the heat transfer, potentially affecting overall heating performance. As work stations in industrial spaces or congregation spaces in heritage buildings are frequently arranged at a significant distance or in sectional zones, for total heating the focus should be on heating the occupants within the space in order to reduce energy consumption. This demands an overview of the distribution of heat required within a given space, achievable through bespoke design, use of bracketry and heater positioning which is focused on driving comfort.

- Instant Heating: While infrared heaters provide quick heat without the need for pre-heating, generally infrared heating may not retain heat like some other systems. As a result, maintaining consistent warmth may require additional operational considerations or insulation measures. The type of infrared heating and design of the heater used also plays a fundamental role here, given that various wavelengths offer different outputs and benefits. In particular, shorter wavelengths are usually more penetrative and therefore transmissive, reflecting heat back into its surroundings from greater heights. As an example, convection towards an object such as a concrete floor will radiate heat back which will keep an environment warmer for longer.

Mythbusting Infrared Heating Disadvantages

Considering the capabilities of infrared heating allows us to leverage it to its fullest. An important series of questions we often ask our customers includes:

- Do you need a full heating scheme to cover the whole floor area?

- If yes, should more-effective zone control be the solution in the case where areas do not require heating for part of the day? (e.g. during operational hours or congregational hours)

- If full heating isn’t always required, what areas have the most footfall and which areas require the most heat?

Typically we find that the response is consistent. For total heating of warehouses and operational facilities, bays need better control zones to heat occupants where the heat is required as opposed to simply warming the whole volume of space. For heritage building projects, occupancy heating and the comfort of the congregation, churchgoers and members is the central requirement whether a full heating scheme is required or not. Fundamentally, full control which saves more energy and improves efficiency is the most important outcome across the whole space.

Built into our specification service Tansun offers modulation across our heaters to provide full controllability, adaptability and flexibility. PIR detection sensors ensure that heaters are only active when needed, automatically switching on when personnel or churchgoers are detected in its vicinity. Black bulb sensing further ensures set point control and maximum output is achieved as quickly as possible, before reducing energy consumption whilst retaining desired temperature.

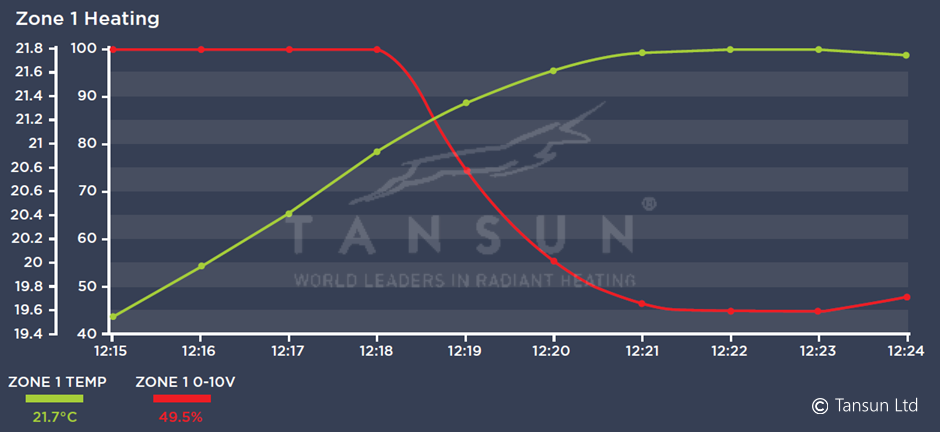

Example of a live demonstration recorded against an Apollo heater, Zone 1 (Area 1) temperature continues to increase where energy consumption decreases after reaching a set point.

Fundamentally our heating solutions are designed to maximise energy savings according to your facility or building requirements. With modulation, Tansun heaters can be dimmed to result in viable energy savings. With no pre-heating time, the energy efficiency of our heaters is improved with instant and targeted heating. There are additionally no requirements for annual inspections or servicing, owing to the low maintenance of infrared heating plus the quality components we use as a British manufacturer with 40 years of engineering experience.

We'd love to discuss your building requirements particularly if energy consumption and savings are integral to your objectives in meeting net zero targets. Take the next step by visiting our website and get in touch with us today. Let's work together towards an energy-efficient future.